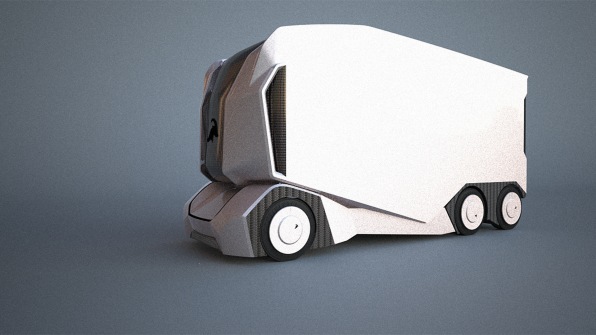

As reported by Engadget: Toyota built a larger sibling for the hydrogen fuel cell powered Mirai, a semi truck. The automaker is testing a water-expelling big rig at the Port of Los Angeles that it hopes will yield data that will help build a fleet of zero-emission trucks.

Called the "Portal Project," the study will determine how well hydrogen fuel-cell heavy duty vehicles work in a shipping environment. The truck itself will be use two Mirai fuel cell stacks and a 12kWh battery to power two motors connected to the rear wheels working in parallel. With a range of over 200 miles per fill up, the truck can haul a gross combined weight capacity 80,000 pounds.

"We think that there's a market demand for this technology in the ports today and there are no there are no competing services to diesel solutions," said Craig Scott national manager of Toyota's advanced technology group.

Tony Gioiello, deputy executive director of port development for the Port of Los Angeles said "the Port of Los Angeles has been a leader in working to reduce pollution from port operations, and we're excited at the potential for a true zero-emission heavy-duty truck to push our Clean Air Action Plan even further."

The truck and the project are part of Toyota's larger plan to help kick start an infrastructure for hydrogen fuel cell vehicles like the Mirai. Initially the automaker will hire its own driver to help collect data on the big rig and it's trips. But it eventually hand the keys over to the driver of a yet-to-be-determined shipping partner.

Called the "Portal Project," the study will determine how well hydrogen fuel-cell heavy duty vehicles work in a shipping environment. The truck itself will be use two Mirai fuel cell stacks and a 12kWh battery to power two motors connected to the rear wheels working in parallel. With a range of over 200 miles per fill up, the truck can haul a gross combined weight capacity 80,000 pounds.

"We think that there's a market demand for this technology in the ports today and there are no there are no competing services to diesel solutions," said Craig Scott national manager of Toyota's advanced technology group.

Tony Gioiello, deputy executive director of port development for the Port of Los Angeles said "the Port of Los Angeles has been a leader in working to reduce pollution from port operations, and we're excited at the potential for a true zero-emission heavy-duty truck to push our Clean Air Action Plan even further."

The truck and the project are part of Toyota's larger plan to help kick start an infrastructure for hydrogen fuel cell vehicles like the Mirai. Initially the automaker will hire its own driver to help collect data on the big rig and it's trips. But it eventually hand the keys over to the driver of a yet-to-be-determined shipping partner.

John O'Dell over at Trucks.com has the exclusive, behind-the-scenes story of Toyota's quest to build a fuel cell big-rig. The whole thing is an excellent read, revealing how Toyota managed to build this fuel cell-powered rig in roughly seven months, using two fuel cell stacks sourced from the production Toyota Mirai to power a custom-designed electric motor cranking out 670 horsepower and 1325 lb-ft of torque.

But it's the truck's performance that really blew our minds. Trucks.com reports that the 21,970-lb. Project Portal truck can accelerate from 25 to 55 miles per hour in just 6.3 seconds. Even better, a Toyota spokesperson tells Road & Track that the unladen rig can sprint from a stop to 60 mph in roughly 10 seconds.

That means the Toyota big rig would run neck-and-neck in a stoplight drag race against a bone-stock 1970 BMW 2002—though the more powerful 2002 tii, with its 9.0-second 0-60, would trounce the Class 8 truck.

Still, that's outrageous acceleration from a vehicle that tips the scales at nearly 11 tons before you hitch up the trailer. And as Toyota illustrates with video evidence, it absolutely runs away from a conventional big-rig pulling an identical, empty trailer from a standing start.